Samurai Katana Swords for True Collectors

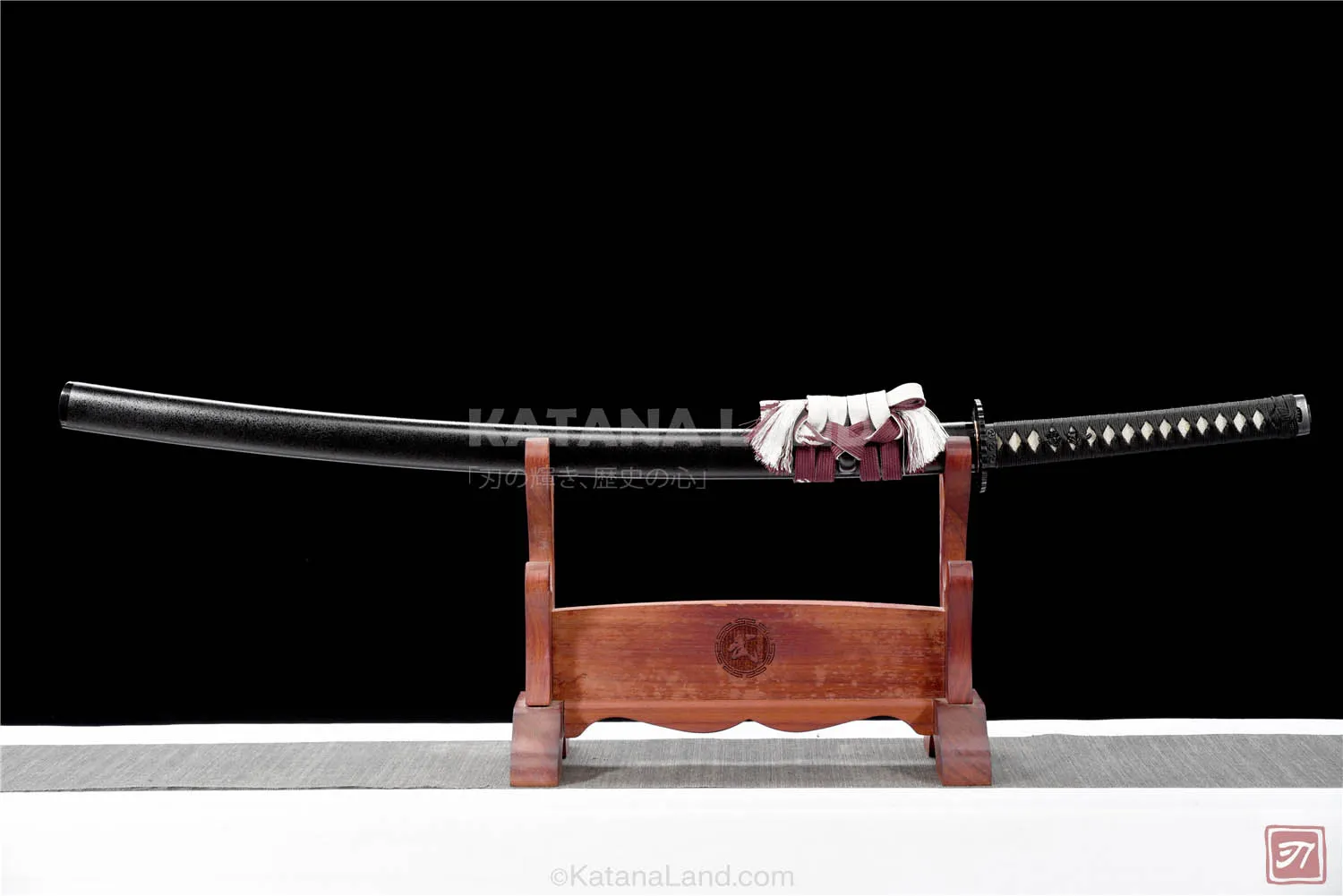

Our katanas are hand-forged by skilled blacksmiths, drawing on over 2000 years of Japanese sword-making tradition. Perfect for collectors and fans of Japanese culture, these swords make stunning display pieces and meaningful additions to any collection.

Samurai Katana Swords for True Collectors

Our katanas are hand-forged by skilled blacksmiths, drawing on over 2000 years of Japanese sword-making tradition. Perfect for collectors and fans of Japanese culture, these swords make stunning display pieces and meaningful additions to any collection.

Best Selling Japanese Samurai Swords

You will love our authentic katana swords.

Real Katana, Forged by Hand

At KatanaLand.com, we offer real katana swords hand-forged by skilled blacksmiths using traditional techniques.

We don’t aim to be the cheapest—our focus is on delivering the highest quality Japanese katana swords.

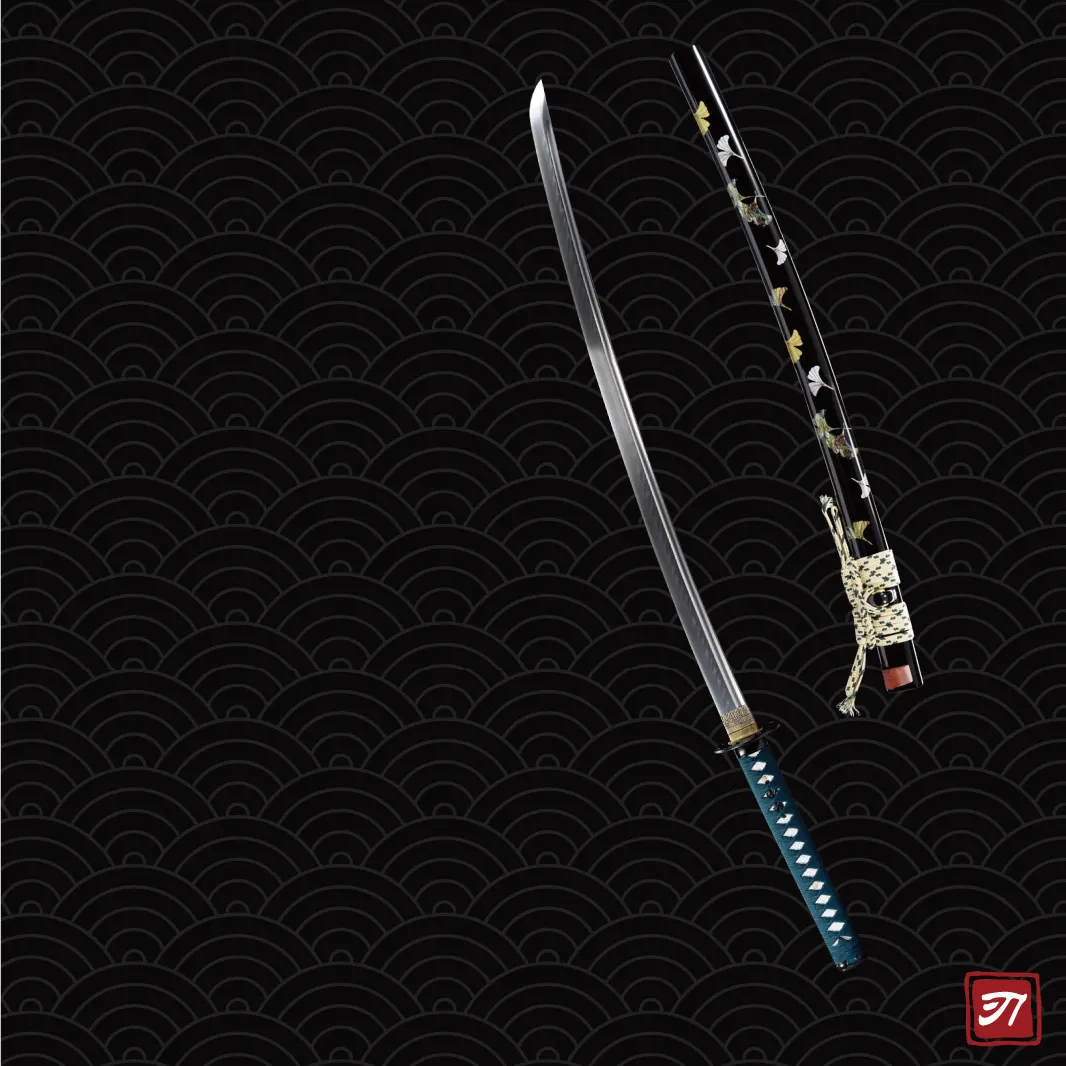

Our collection of Katanas, Tachis, Wakizashis, and Tanto knives are crafted to be proudly displayed or added to any collection.

If you're seeking an authentic katana for sale that embodies both craftsmanship and tradition, our collection offers exactly what you're looking for.

Every katana we offer reflects the true spirit of the samurai.

For Every Collector

We offer a wide range of samurai swords, including options made from T10 Steel, High Carbon Steel, Damascus Steel, Medium Carbon Steel, Manganese, and Spring Steel—each with unique qualities to suit your needs.

You can also choose from a variety of colors, including black, blue, gold, silver, and red, so your katana will stand out in any collection.

Whatever your style, we have a katana that combines strength and beauty, tailored to your taste.

FAQ

Can't found what you're looking for? Contact us

Katana swords are traditional Japanese weapons, famous for their curved blades and exceptional craftsmanship. They were primarily used by samurai, the warrior class of feudal Japan. The design of the katana is unique. The blade has a slight curve, which allows for quick and precise strikes.

They are all traditional Japanese swords, each with its own unique characteristics and purpose.

The tachi is the longest of the three, typically worn suspended with the edge facing down. It was primarily used by samurai during the Heian period. Its longer blade made it ideal for cavalry combat and quick, sweeping cuts.

The wakizashi is a shorter sword, often paired with the katana to form a set known as "daisho." The wakizashi was used for close combat, as well as for ritual purposes, such as seppuku (samurai suicide). It also served as a sidearm when the samurai needed to move through crowded spaces or indoors.

The tanto is the smallest of the three, a dagger-like sword that was used both as a weapon and for ceremonial purposes. Its short blade made it practical for close-quarters combat. In times of peace, it was often worn as a sign of status or used in rituals, such as a samurai’s formal attire.

The creation of a katana begins with selecting the right materials. High-quality steels such as Damascus steel, T10 steel, manganese, and spring steel are carefully chosen for their durability and strength.

Once the steel is obtained, the next step is folding. The metal is heated and hammered repeatedly, folding it over itself to remove impurities and evenly distribute the carbon. This process can be done up to several dozen times, resulting in a blade that is both strong and flexible.

After the folding, the steel is shaped into the rough form of the blade. This is done by heating the metal and using a variety of tools to shape it. The smith will carefully refine the blade, paying close attention to the curvature and the geometry.

The most important part of the forging process is the heat treatment. The swordsmith applies clay to the blade in a specific pattern. The blade is then heated and rapidly cooled in water, which hardens the edge while leaving the spine softer. This differential hardening creates the signature "hamon," or temper line, visible on the blade.

After the blade is forged and hardened, it is polished with a series of stones of different grits. This polishing process not only sharpens the edge but also brings out the beauty of the steel, including the unique grain patterns. The final touch is assembling the sword, which includes the handle (tsuka), guard (tsuba), and sheath (saya), all of which are carefully crafted to complement the blade.

The entire process can take weeks or even months, depending on the skill of the swordsmith and the level of detail involved.

Yes, it is legal to own a katana sword in many places, including the United States and Europe, as long as it is for personal use, collection, or display. However, there are certain regulations you should be aware of. In the USA, you cannot carry it openly in public. It must be kept at home or in private settings. Additionally, you must be at least 18 years old to purchase a katana.

A bo-hi (also known as a fuller) is a groove or channel carved into the flat side of a katana blade. The bo-hi serves two main purposes.

First, it lightens the blade by removing some material, making it easier to wield. This reduction in weight allows the samurai to draw and strike with greater speed and precision. In ancient times, the bo-hi also had a practical purpose as a blood groove. The channels helped to channel the blood away from the wound, allowing enemies to lose blood more quickly during battle.

Today, the bo-hi is primarily an aesthetic feature. It enhances the appearance of the katana, giving it a sleek, elegant look. A katana with a well-defined bo-hi is often considered more visually striking, adding to the sword's overall beauty.

Hamon is the visible temper line found on a katana blade, created through the heat treatment process. When forging a katana, the blade is coated with a layer of clay, leaving the edge exposed. The sword is then heated and rapidly cooled in water, a process known as quenching. The difference in temperature between the edge and the spine of the blade causes the steel to harden at different rates.

As a result, the edge becomes much harder than the rest of the blade, giving it the sharpness needed for cutting, while the spine remains softer and more flexible. The clay coating helps to create this difference in hardness, and the resulting hamon is the striking, wavy line that marks the transition between the hardened edge and the softer spine.

Yes, we can ship to locations worldwide.

You can contact our customer support team by emailing us at [email protected].